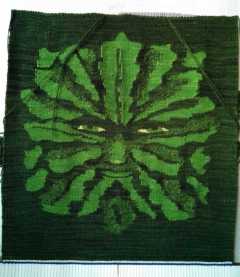

The weaving completed, I cut the Green Man off the loom on January 13, 2014

…only 1 year later than planned.

Now the finishing work began: all the warp threads knotted and secured, the long gap in the center forehead leaf sewn shut, clean up the back (weave in/sink the weft ends), plus there was a lot of rippling in the tapestry because my warp tension had become very uneven.

Crossing my fingers that blocking would eliminate the rippling, I put him onto the shower floor to wet down then I pinned him facedown onto a piece of foam board to block, squaring up the 4 sides. I stood him up in the bathtub to drain over night then moved the board near the floor register for the next 4 days to dry.

Once he was throughly dry, I unpinned him and turned him over. To my joy…. the blocking had eliminated the rippling = whew!!! Twill tape was sewn to the top and bottom, turned to the back and sewn down. Finished tapestry dimensions: 18″ x 18″. I used velcro to mount him onto black matboard and made a simple black frame. Final dimensions: 25″ x 25″. I packed him up and dropped him off to be juried.

The Green Man was accepted for the AAFG 2014 exhibit at the Power Center for the Performing Arts in Ann Arbor, MI. We hung the exhibit on Tuesday, February 4th and it runs through the month of February.

He is nicely positioned so he can check out everyone as they enter the theater from the lobby…. and is watching to make sure no food or drink is brought inside!

My daughter Andrea, who did the orignal painting, announced the other day, “Hey, Mom…. I’ve got an idea for our next painting/tapestry collaboration….. “